Liptovský Trnovec aquapark Tatralandia – Tatralandia Tropical Paradise

Author: Ing. arch. Marián Goč, Ing. arch. Dávid Goč

Main contractor: Riastav s.r.o.

Investor: Tatry Mountain Resort, a.s.

Statics: Ing. Fedor Bet’ko

Supplier of the wooden load-bearing structure: Kontrakting stavebné montáže, s.r.o.

– Production and assembly documentation: Ing. Juraj Pečeňanský

– Construction manager: Ing. Tomáš Horník

In an effort to significantly improve the services in the Aquapark, the investor decided to build new premises (Stage I), roof the existing pools and add some functions in their immediate vicinity (Stage II).

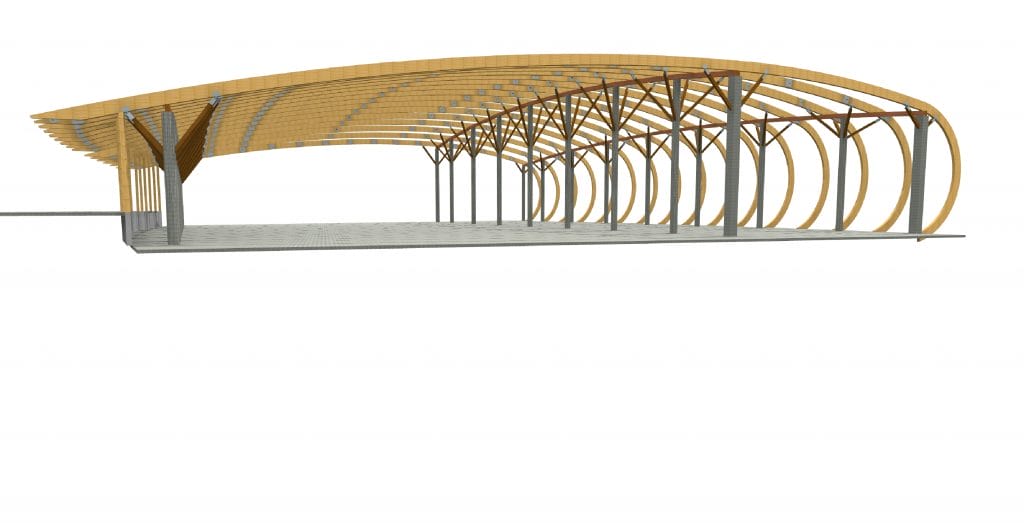

The architectural composition of the space follows the main motifs of the complex and existing buildings: water – water world – water vessels – well-being – relaxation – rest. The roofing, which is immediately connected to the main operational building, evokes the shape of a characteristic element of the water world – a shell, which allows the use of progressive foil materials to cover the space, regulating the transparency and translucency of daylight. The author of the architectural concept is Ateliér GAM, s.r.o. from Ružomberok – Ing. arch. Marián Goč and Ing. arch. Dávid Goč.

The main load-bearing structure of the roof consists of arched beams made of glulam timber laid on reinforced concrete columns and inclined struts. This creates a roof with a floor plan of 55 m, tapering to 35 m, 58 m long, covered with ETFE transparent thermal insulation double foil, creating a shell-shaped roof. A built-up area of more than 2,000 m² creates a built-up area of approx. 30,000 m³. 16 pieces of wooden beams made of glulam timber, spaced from 2.3 to 3.8 meters apart, are planted with steel leeward crosses in the outer fields. The gable leeward beams absorb the forces from the roofing foil. The stiffening of the roof structure is also provided by horizontal steel horizontals located across the entire width in ten places. The wooden beam itself is composed of four segments for production, transport and assembly reasons. The construction is subtle and allows maximum illumination of the covered space. Inclined struts transfer the load from the main beams to the reinforced concrete columns. At the point of the largest span of 30 m, a wooden “frame insert” is inserted into the brackets to reduce the span to 18 m. In the calculation, the decreasing coefficients from the temperature Ct and from the topography Ce (from the blowing of the snow by the wind) were considered for the snow load. The static design of the structure was developed by Ing. Fedor Betko.

The implementation documentation, production and assembly of the wooden supporting structure were provided by the companies of the Kontrakting group – KONTRAKTING KROV HROU, s.r.o. and Kontrakting stavebné montáže, spol. s r.o. Due to the ongoing season, the investor divided the implementation into two stages. The first stage took place in May and June 2012, new spaces were created and covered with beams from two segments. The construction was completed with a temporary wooden wall. From September to November, the second stage took place, in which the pools were covered with the construction of beams from the third and fourth segments, following the first two segments from the first stage.

Read more about prefabricated houses made of wood or contact us for a consultation.